Designing a safe forklift battery charging room

The use of battery electric forklifts continues to rise as company’s become more conscious of their corporate social responsibilities, aiming to have as little negative environmental impact as possible from their operations.

As such battery electric forklifts are seen as a more environmentally friendly alternative to combustion engine forklifts.

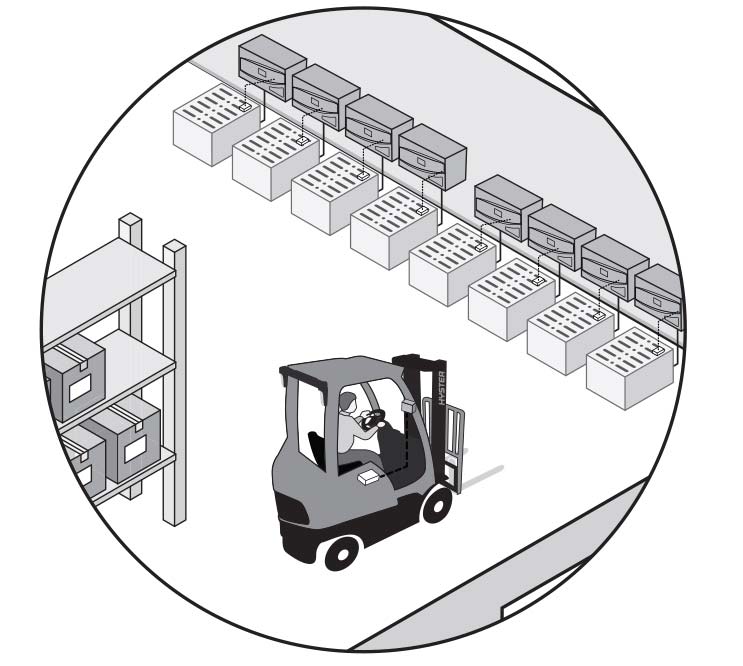

Due to environmental and operational factors such as impact of water and lighter lifting capacities, battery electric forklifts are most often used in warehouse applications.

Whether running an individual unit or a fleet of forklifts you will need to have a designated battery charging station to charge batteries when necessary.

This blog post will look at battery charging room design, setting out some key design considerations that will ensure a safe battery charging room.

Proper ventilation

Whilst recharging and for a short period after the charge is complete forklift batteries give off hydrogen gas, which is why proper ventilation is vital to ensure the safety of workers in the immediate vicinity of battery charging equipment.

As hydrogen gas is both colourless and odourless it is hard to detect and is very dangerous. If a hydrogen in air mixture of 4% or greater is present, there is a substantially increased risk of an explosion. To ensure this risk is mitigated it is recommended that a hydrogen concentration of under 2% is kept at all times.

Ventilation can be provided via natural means such as openings at the top of buildings or can be mechanically assisted through the installation of exhaust fans.

Acid resistant flooring

Due to the corrosive nature of battery acid, the flooring of a charging room must be resistant to acid damage, which will also lead to an easier clean-up in the event of a spill. Without an acid resistant floor structural damage may occur in the event of a spill.

Ensure correct safety equipment is readily available

It is essential that the correct safety equipment is readily accessible should an emergency occur. A fire extinguisher that is suitable for use on electrical fires, along with an eye wash and emergency shower to deal with accidental acid splash are essential to employee safety.

Correct charging point installation

When designing a battery charging room it is essential that charging points are installed correctly. Chargers should be wall mounted and fitted with emergency stop breakers to stop the flow of electricity in an emergency.

Wall mounted chargers should be positioned so that when connected any wiring does not exceed 1 metre in length as this is a tripping hazard.

When charging multiple units at once there should also be a minimum of 1 metre gap the whole way round each vehicle for easy access when necessary.

Contact us for your battery charging needs

Adaptalift stocks a large range of battery electric materials handling units. With our knowledge and design expertise we are also able to provide full turnkey charging station solutions for your fleet.