5 Considerations to Understanding a Forklifts Lifting Capacity

All forklifts and materials handling equipment (MHE) have a maximum lift capacity as specified by the manufacturer.

The overall rated capacity of a forklift is calculated based on a number of factors to specify the maximum weight a forklift or MHE can safely lift at any one time.

This week’s blog looks at 5 key consideration to help understand a forklifts lifting capacity.

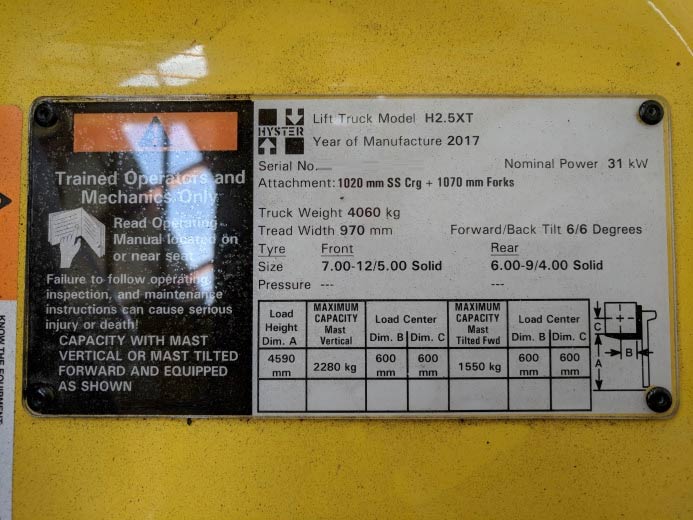

1. Make sure that the forklift’s load capacity data plate is legible, fitted and up to date

All forklifts and materials handling equipment has a maximum lift capacity that has been calculated and specified by the manufacturer.

This information must be clearly displayed on all units, so all operators are able to have the information readily to hand before and during operation.

All information relating to the units lift capacity are displayed on the units data plate.

These are installed as part of the manufacturing process and will remain accurate based on the unit’s configuration from manufacture.

If the unit is modified in any way such as the installation of an attachment the units must be rerated by the manufacture to include the change in specification from the attachment.

2. Know the capacity of your forklift and never exceed it

Before operating a forklift it is imperative that the forklift’s maximum lift capacity is known.

If the forklifts maximum lift capacity is exceeded it may lead to a number of problems including:

- Operator or employee injury

- Operator or employee fatality

- Product damage or loss

- Capital equipment (e.g. forklift, racking or pallets) damage or loss

The units maximum lift capacity is clearly shown on the units rating plate as outlined in tip 1.

A forklift unit’s capacity decreases the higher the load is lifted in the air.

This is based on the units load centre and ability to remain stable when lifting the heavy load up high.

The example rating plate in tip 1 shows that the forklifts maximum lift capacity is 2,280kg when lifting to the maximum height of the mast at 4,590mm high.

3. Know your forklifts load centre

It is a common misconception that a forklift can lift its maximum rated load to its maximum lift height, this is incorrect.

When undertaking lifting operations a forklift can be viewed like a see-saw, with the front axle of wheels acting like the fulcrum of a see-saw.

When picking up a load on tynes the front end of the unit becomes top heavy, built in counterbalances negate this added weight to ensure the unit stays level and doesn’t tip over.

The lift capacity of a forklift at extended heights is governed by the load centre being lifted.

The load centre is the balance point of a load where it will be evenly balanced whilst sitting horizontally on tynes with one end of the load butting up against the carriage.

The further towards the end of the tynes the load centre is, the units lift capacity decreases to ensure the unit doesn’t become top heavy and overbalance forwards.

The graph below shows the decrease in rated load capacity the further towards the end of tynes the load centre becomes.

4. Buy or hire a forklift with larger capacity than necessary

When hiring or purchasing a forklift or MHE it is always advisable to choose a unit that has a slightly larger lift capacity than the weight of your maximum load.

Not only does this ensure you will never exceed the units maximum lift capacity, but also provides extra flexibility in the future to lift heavier loads if necessary.

The added flexibility of being able to lift heavier loads when necessary can provide significant time and cost savings to your operations.

The unit is already on site so can immediately un/load or move the good straight away, rather than having to wait whilst a larger capacity forklift is procured.

Not having to procure a larger forklift eliminates the need to spend further funds on hiring a larger capacity forklift to complete the operations, particularly expensive it necessary for multiple one off lifts.

5. Never assume a loads weight, always check

All operators must be trained to double check the weight of a load before they lift.

Often for large loads the total load weight is specified on the pallet or item, however to always ensure accuracy loads should be weighed on a scale or a weight scale should be installed onto the forklift such as the weight scale system that can be integrated as part of the Forktrack telemetry system.

The major benefit of installing a weight scale system such as Forktrack is improved efficiency and less time wasted as the load weight can be measured simply via the operator lifting it up.

The load doesn’t need to be unnecessarily moved to be placed on an industrial scale to be weighed first.

For further assistance in understanding your forklifts lifting capacity or to find the ideal forklift for your requirements speak to our team on 13 22 54 or email us.