Forklift Fundamentals: Your Complete Terminology Guide

Are you new to forklifts or just need a quick refresher?

Welcome to our guide of forklift terminology, where we’ll cover the basics of what you need to know about forklifts, including:

- The different types of forklifts available.

- Key components of a forklift.

- Types of forklift masts and their key terminology.

- Main dimensions of a forklift.

- Understanding stability, manoeuvrability and gradeability.

- Types of forklift tyres.

Types of Forklifts and Materials Handling Equipment (MHE)

The Australian Forklift and Industrial Truck Association (AFITA) list eight distinct classes that forklifts and MHE can be classified under, classification of a forklift is based on factors including: applications, fuel and tyre types and unit features.

- Class I – Electric motor rider forklifts

- Class II – Electric motor narrow aisle forklifts

- Class III – Electric motor hand pallet jacks, stackers and tow tractors

- Class IV – Internal combustion engine cushion tyre forklifts

- Class V – Internal combustion engine pneumatic tyre forklifts

- Class VI – Electric or internal combustion engine tow tractors

- Class VII – Rough terrain forklift

- Container Handling

For an in-depth description of each of the above classes refer to this post.

Each of the AFITA’s forklifts classes contain a range of different types of equipment with some of the most common and popular being:

- Manual Hand Pallet Jack

- Battery Electric Pallet Jack/Truck

- Walkie Stacker

- Walkie Reach Stacker

- Low Lever Order/Stock Picker

- Medium – High Level Order/Stock Pickers

- Reach Truck

- Counterbalance Forklift

- Side-loader/Multi-directional Forklift

- Articulating Narrow Aisle Forklift

- Very Narrow Aisle (VNA) Forklift

- Rough Terrain Forklift

- Telehandlers

- Truck Mounted Forklift

- Container Handler

- Empty Container Handler

- Straddle Carrier

Read this post for full descriptions of each of the unit types in the list above.

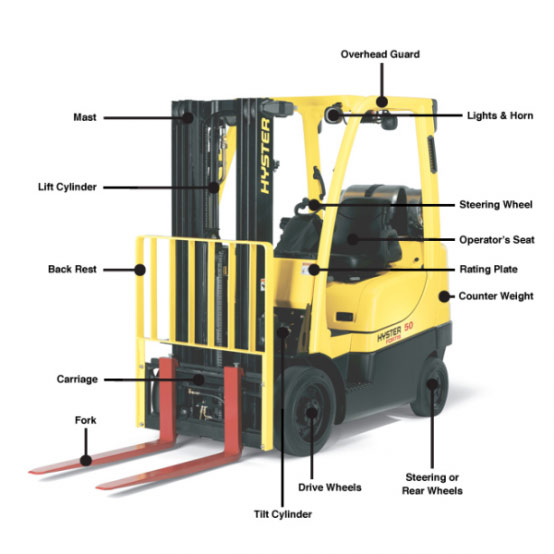

Basic Forklift Components

At the heart of every forklift are its key components:

- Mast: This vertical support allows the raising and lowering of loads.

- Carriage: It’s where the fork* s are attached.

- Back Rest: Prevents load shifting backward, ensuring operator safety.

- Fork (Tynes): The arms that engage the load.

- Lift Cylinder: Controls vertical movement.

- Overhead Guard: Provides operator protection from falling objects.

- Tilt Cylinder: Controls tilting of the mast and forks.

- Rating Plate: Indicates the maximum load capacity.

- Counterweight: Adds stability under load.

Forklift Mast Types

The three most common types of forklift mast are:

- Duplex – 2 Stage

- Triplex – 3 Stage

- Quad – 4 Stage

Common forklift mast terms:

- Lift Height: Maximum height the forks can reach.

- Free Lift: Height the forks can be raised without extending the mast.

- Lowered Height: Height of the mast when fully lowered.

- Extended Height: Maximum height of the mast when fully extended.

Forklift Dimensions

It is crucial to understand the basic dimension terms of length, width and height of a forklift to ensure a unit will fit and is safe to operate within the workspace,* *

Overall Length: From the front end of the fork arm to the back end of the forklift.

Overall Height: Measured from the ground to the highest point.

Overall Width: Width of the forklift, essential for manoeuvring in tight spaces.

Forklift Stability, Manoeuvrability and Gradeability

When lifting heavy loads up high stability and manoeuvrability is paramount, key terminology that needs to be understood includes:

- Load Capacity: Maximum weight a forklift can carry.

- Load Centre: Distance from the face of the forks to the load’s centre of gravity.

- Stability Triangle: Area under the forklift to maintain stability.

- Tilting Angle: Maximum angle the mast can tilt.

- Right Angle Stacking Aisle: Determines the maximum load a forklift can carry and turn.

- Gradeability: The effect the angle of a ramp or slope has on a forklift carrying a load.

Forklift Tyre Types

The location and environment a forklift is going to be operating in will play a role in determining what type of tyre is fitted, some of the most common types of forklift tyres are:

- Pneumatic: Used in unpaved yards and on rough terrain surfaces.

- Pneumatic Profile Puncture Proof (Semi-Solids): Used on sealed surfaces and areas where punctures may be an issue.

- Cushion: Used on more compact model forklifts in warehouse applications.

- Non-Marking: Made to eliminate black marks on the floor.

Factors that need to be considered when selecting the correct tyre for a forklift include:

- Truck type

- Load conditions

- Application: working cycle

- Floor conditions

- Driver

- Risk for external damage

- Tyre construction

- Thickness of thread layer

- Profile

- Heat build-up

- Choice of rubber compound

- Non marking tyres are softer and wear faster

Discover some of the key considerations that must be evaluated when choosing the best tyre for your forklift in this post must be evaluated when choosing the best tyre.

Whether you’re delving into the world of forklifts for the first time or refreshing your knowledge, this guide has equipped you with essential terminology and insights. From understanding the diverse types of forklifts to grasping the significance of key components like masts and tyres, you’re now primed to navigate the nuances of forklifts with confidence.